In oyster grading, shape and size are the two most important factors that determine market value, especially for half-shell oysters sold to restaurants and raw bars. Here's a quick breakdown:

- Shape: Deep cups, uniform proportions, and clean, symmetrical shells are prized for their visual appeal and ease of shucking. A well-shaped oyster holds its liquor better and looks more attractive on a plate.

- Size: Measured by shell length, oysters are categorized into sizes like cocktail (2.5–3 inches), market (3.5–4 inches), and large (4–5 inches). Half-shell buyers prefer oysters in the 3–4.5 inch range, while larger oysters are often used for cooked dishes.

Virginia oyster farms, such as Little Wicomico Oyster Co., use precise grading systems to ensure consistency in both shape and size. This attention to detail helps them meet the high standards demanded by premium raw-bar markets and wholesalers. For example, their Blackberry® Reserve Oysters are a top-tier product priced at $189.00 for their largest seasonal option.

Key takeaway: Shape is critical for presentation and ease of handling, while size determines market category and pricing. Together, they influence how oysters are graded, marketed, and priced across different segments of the seafood industry.

Oyster Grading in Virginia

Virginia oyster farms follow a carefully structured grading process that starts as soon as oysters are harvested. Right after being pulled from the water, the oysters are rinsed and sorted to remove any that are dead, broken, or fall below the 3-inch minimum size. From there, the remaining oysters are sorted both mechanically and by hand based on their shell size and shape. Mechanical graders divide them into "small", "market", and "select" categories, focusing on the preferred size range of 3–4.5 inches. After this, hand culling takes it a step further, discarding oysters that are overly flat, thin, or misshapen. Only the oysters with a deep cup, uniform shape, and the ability to retain liquor make the cut.

Throughout the grading process, growers aim for consistency in size and shape. Oysters with good form but undersized shells are sent back to grow, while larger but misshapen ones are downgraded. This process ensures that every batch of oysters meets the quality standards that wholesalers and restaurants expect. By focusing on both dimensions and visual appeal, Virginia oyster farms maintain a reliable grading system that defines each category clearly.

Grading Terms and Standards

In the mid-Atlantic oyster trade, in-shell oysters are typically divided into three grades: select, choice (sometimes called "market"), and standard. Select oysters are the top-tier option - large, well-shaped, with deep cups and full meats, often slightly exceeding the 3–4.5 inch range. These oysters fetch the highest prices. Choice or market oysters fall within the core size range, offering good shape and decent cup depth, making them ideal for most restaurant half-shell menus. Standard oysters meet the minimum size requirement of about 3 inches but tend to be flatter or less uniform. They’re better suited for cooked dishes or house specials rather than premium raw-bar presentations and are priced accordingly.

It’s important to note that these grading terms aren’t federally regulated, so specific measurements can vary slightly between growers. However, the grading principles remain consistent across Virginia: select and choice grades emphasize appearance - focusing on shell symmetry, cup depth, and cleanliness - just as much as size. This means two oysters of the same length could end up in different grades depending on their shape and overall look.

Why Consistent Grading Matters

For restaurants and wholesalers, uniformity in size, shape, and meat yield within each grade is critical. When a chef orders a "select" oyster or a premium Virginia brand like Blackberry® Reserve Oysters, they expect every oyster in the shipment to be similar in size, with deep cups and full meats. This level of consistency ensures smooth plating, predictable shucking times, and a reliable guest experience. On the flip side, inconsistent grading - mixing sizes or cup depths - can lead to uneven plating, longer prep times, and unpredictable costs, all of which can hurt both customer satisfaction and profit margins.

Uniform grading also makes inventory management and pricing discussions much easier. A "select" oyster from any Virginia farm should meet the same expectations, creating trust and reliability for buyers. For Virginia oyster brands competing in national raw-bar markets, delivering consistent and well-defined grades is essential for securing repeat business and building strong, long-term relationships with restaurants and wholesalers.

Shape in Oyster Grading

Virginia's strict grading standards highlight the importance of shape in determining an oyster's market value. The shell's shape is a key factor in deciding whether an oyster earns the premium "select" grade or is categorized as standard. For instance, two oysters of the same 3.5-inch size can fetch significantly different prices depending on their cup depth, symmetry, and proportions. For Virginia oyster farms aiming to supply the half-shell market, achieving the ideal shape is just as critical as meeting size requirements. By understanding these shape criteria, it's clear how even slight variations can lead to notable differences in value.

Key Shape Characteristics

When sorting half-shell oysters, graders and buyers focus on several essential shape attributes. One of the most important is cup depth - a deeper cup enhances both the oyster's appearance and its ability to hold meat and liquor. The industry often refers to the ideal ratio of 1:2:3 for cup depth, width, and length. To avoid shells that appear overly long and flat, the width should be at least 40–45% of the total length. Symmetry is another vital factor; oysters with balanced and regular outlines are easier to arrange attractively, while twisted or uneven shells can create challenges for display.

The hinge structure also plays a crucial role. A sturdy, compact hinge helps keep the oyster tightly closed during transport, preserving its liquor and overall quality. Shuckers prefer hinges with a clean entry point for their knives. While a slightly curled umbo is acceptable, bulky or twisted hinges can make shucking more difficult and increase the risk of shell damage. Additionally, shell thickness and lip strength are important for durability. Thick shells are less likely to break and reduce the chances of fragments mixing with the meat, while thin, brittle edges are more prone to chipping and can even cause injuries during shucking.

How Shape Affects Half-Shell Value

These specific shape traits directly contribute to the value of half-shell oysters. Shape impacts three key aspects that high-end restaurants prioritize: presentation, shucking efficiency, and meat yield. Oysters with deep cups and balanced shells look more appealing on the plate and allow chefs to arrange them neatly.

For shuckers, who may process hundreds of oysters in a single shift, small differences in shape can significantly affect labor efficiency. Oysters with strong, accessible hinges are quicker and safer to open, while irregularly shaped ones slow down the process and increase the risk of breakage. Additionally, deeper cups improve the meat-to-shell ratio, allowing the oyster's adductor, belly, and mantle to fully develop. This results in a plumper, more visually appealing oyster. On the other hand, shallow, plate-like shells often yield thinner meats that dry out faster on the raw bar and hold less oyster liquor.

To meet these demanding standards, many Virginia farms, including operations like Little Wicomico Oyster Co., use tumbling and floating bag systems. These methods help produce single, deep-cupped oysters that align with the high expectations of selective buyers.

sbb-itb-5051793

Size in Oyster Grading

Alongside shape, size is another key factor in how oysters are categorized and priced in the market. While shape affects handling and visual appeal, size is used to classify oysters for commercial purposes. In Virginia, oyster farms use shell length - measured from the hinge to the farthest edge of the shell - as a quick and reliable way to gauge size. This measurement not only provides consistency but also correlates closely with the volume of meat inside the shell. As a result, shell length has become the standard for grading oysters commercially.

Size Measurements and Categories

For Eastern oysters sold in-shell, size categories are typically based on shell length and include:

- Cocktail: about 2.5–3 inches

- Small or Petite: around 3–3.5 inches

- Market or Medium: approximately 3.5–4 inches

- Large or XL: about 4–5 inches

- Jumbo: over 5 inches

These size distinctions make it easier for chefs and buyers to choose oysters for specific culinary uses. Many Virginia farms aim for the 3–3.5 inch range, which is highly sought after for premium raw-bar selections. Larger oysters, on the other hand, are often directed toward cooked dishes or sold in bulk.

For shucked oysters, size is graded differently - based on the number of meats per gallon. Fewer meats per gallon indicate larger, more substantial pieces.

Both grading systems play a direct role in determining market applications and pricing strategies.

How Size Affects Market and Pricing

Size significantly shapes how oysters are marketed and priced. Smaller oysters, typically between 2.5 and 3.5 inches, are a favorite at raw bars due to their ideal one- or two-bite size and polished presentation. These oysters are often sold by the dozen and are popular in tasting flights, where their perceived quality and visual appeal allow them to command premium prices despite their smaller meat content.

In contrast, medium and large oysters (3.5–5 inches or more) are better suited for cooking. Their larger meats hold up well under heat, coatings, and sauces, making them perfect for dishes like oysters Rockefeller, stews, or grilling. While these larger oysters may have a higher per-unit price, they often deliver greater value when measured by the amount of meat per dollar.

A good example of how size impacts pricing is Little Wicomico Oyster Co.’s Blackberry® Reserve Oysters, their largest seasonal offering, which are priced between $189.00 and $209.00. This demonstrates how larger oysters can drive profitability for growers.

For oyster farms, finding the perfect balance between size and meat fullness at harvest is essential for maximizing revenue. Meanwhile, restaurants can optimize their menu margins by choosing oyster sizes that deliver the best value in terms of meat-to-cost ratio.

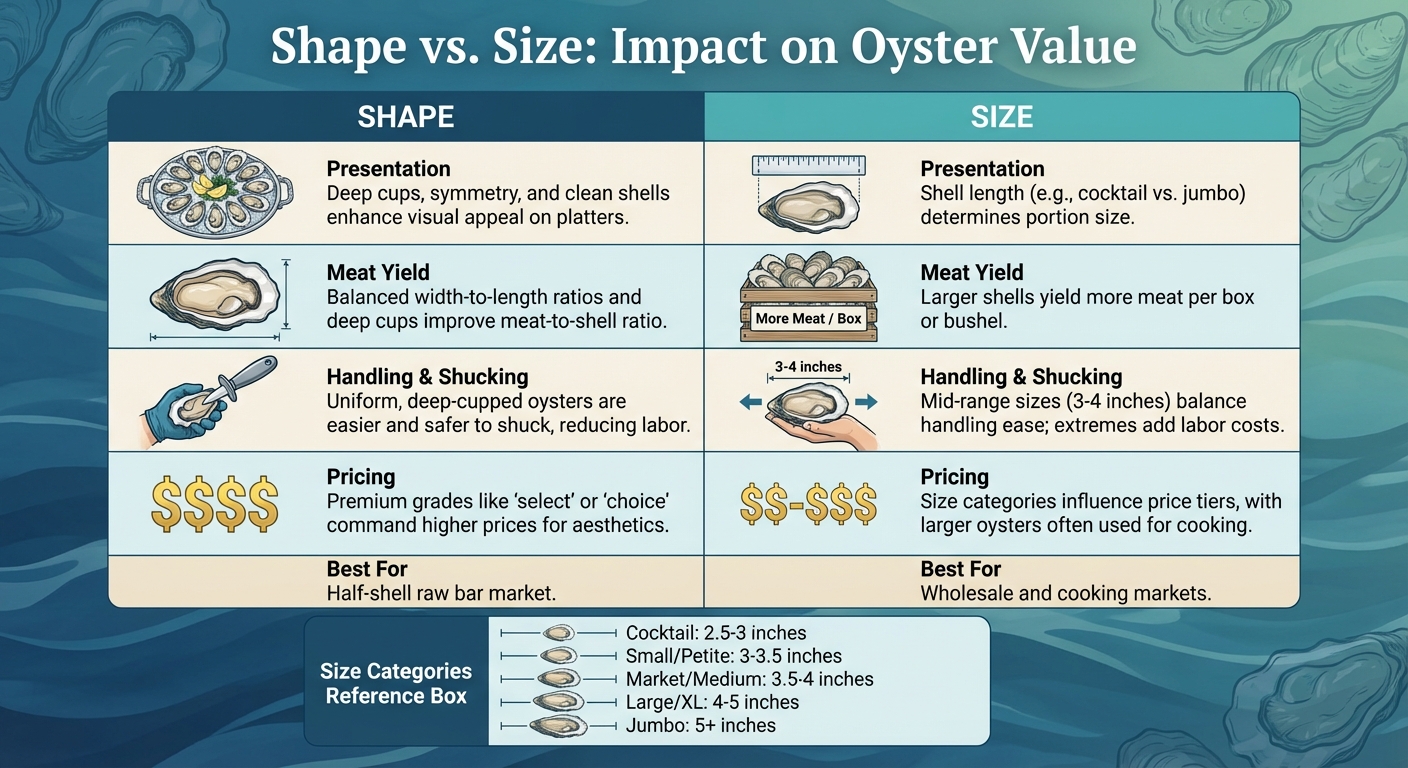

Shape vs. Size: Impact on Value

Oyster Grading: Shape vs Size Comparison Chart

Building on established grading standards, let’s explore how shape and size uniquely influence the market value of oysters.

Both shape and size play a role in determining an oyster's worth, but their importance varies depending on the market. In the half-shell market, shape often takes precedence. A perfectly shaped oyster with a deep cup, even if slightly smaller, is more desirable because it enhances presentation and is easier to shuck. In fact, such oysters can fetch higher prices compared to larger ones with irregular shapes.

On the other hand, size is the primary factor in shucked and wholesale markets driven by volume. In these markets, oysters are categorized by shell length (e.g., 3–4 inches for market oysters) and shucked meat size (like "counts" or "small"). Buyers in these segments prioritize consistent sizing over appearance, as it ensures efficient portioning and predictable yields.

High-end raw bars value the visual appeal of well-shaped oysters, while bulk cooking markets focus on size for maximum meat yield. To maximize value, growers often sort their harvests into shape-focused lots for boutique half-shell customers and size-focused lots for shucking houses.

Comparison Table: Shape vs. Size

| Factor | Shape | Size |

|---|---|---|

| Presentation | Deep cups, symmetry, and clean shells enhance visual appeal on platters | Shell length (e.g., cocktail vs. jumbo) determines portion size |

| Meat Yield | Balanced width-to-length ratios and deep cups improve meat-to-shell ratio | Larger shells yield more meat per box or bushel |

| Handling & Shucking | Uniform, deep-cupped oysters are easier and safer to shuck, reducing labor | Mid-range sizes (3–4 inches) balance handling ease; extremes add labor costs |

| Pricing | Premium grades like "select" or "choice" command higher prices for aesthetics | Size categories influence price tiers, with larger oysters often used for cooking |

These differences highlight the need for growers to fine-tune their farming practices to meet the demands of specific markets.

Virginia Oyster Farming Practices

In Virginia, many farms employ high-density gear such as floating cages, bags, or racks, often paired with mechanical or wave tumbling. These methods promote deeper cups and thicker, more compact shells. Growers carefully monitor growth to harvest oysters at ideal sizes for half-shell markets, typically around 2.5–3.5 inches.

A great example is Little Wicomico Oyster Co., which specializes in sustainably farmed Virginia oysters. They cater to the half-shell market with offerings like Blackberry® Reserve Oysters and Blackberry Oysters. By cultivating their oysters in the Little Wicomico River and using carefully chosen gear and timing, they achieve optimal cup depth and shell symmetry. This allows them to serve both shape-driven raw bars and size-focused wholesale channels, positioning their oysters as a premium product that commands higher prices on menus.

Conclusion

In the U.S., the grading of oysters by shell shape and size plays a key role in determining their value, with preferences differing across market segments. For premium half-shell offerings at raw bars and upscale restaurants, features like deep cups, well-balanced proportions, and clean shells - typically measuring between 2.5 and 3.5 inches - are highly sought after. These characteristics not only ensure a visually appealing presentation but also make the oysters easier to shuck. On the other hand, wholesale and processing buyers prioritize consistent size categories (such as cocktail, market, large, or jumbo) to streamline portion control, predict meat yields, and manage food costs effectively. This dual focus ensures that oysters are tailored to meet the specific needs of both raw-bar and wholesale markets.

Consistency in grading is the backbone of a dependable premium product. Modern aquaculture methods help growers meet the stringent shape and size standards that buyers demand. This reliability reduces waste, lowers labor costs, and fosters trust among chefs and distributors. A great example of this is Little Wicomico Oyster Co., a Virginia grower known for offering carefully graded oysters that meet the high standards of the half-shell market.

For buyers, the advice is straightforward: inquire about grading standards when sourcing Virginia oysters. Understanding how oysters are sorted by shape and size can help ensure the product is a perfect fit for its intended use - whether it’s a raw bar flight, a restaurant menu, or home grilling. A deep-cupped oyster with a 3-inch shell is ideal for half-shell service, while larger oysters with less emphasis on shape are better suited for cooked dishes where meat yield takes priority.

Even though grading terminology may differ, the core principles - balanced shape, appropriate size, and consistent standards - are universally recognized. Virginia’s commitment to transparency and precision in grading not only protects quality but also preserves market value, solidifying the reputation of Virginia oysters as a benchmark in the industry.

FAQs

Why does the shape of half-shell oysters matter more than their size?

The shape of half-shell oysters often matters more than their size because it significantly affects how they look and function. An oyster with a deep, well-formed cup is not only easier to shuck but also retains its liquor better. This makes it more visually appealing when served, which is a big draw for restaurants and diners alike.

Although size does have some importance, the consistency and quality tied to the oyster's shape are the real drivers of its market value and the satisfaction it brings to customers.

How does Virginia maintain consistent standards for grading oysters?

Virginia takes oyster grading seriously by following clear standards that focus on shape and size. These two elements play a major role in defining both the market value and the overall quality of the oysters.

Farms such as Little Wicomico Oyster Co., with four generations of oyster farming experience, uphold rigorous quality control practices. Their dedication to detail ensures that every oyster meets high standards. This level of care helps solidify the reputation of Virginia oysters as some of the best you can find.

Why are deep-cupped oysters a great choice for restaurants?

Deep-cupped oysters are highly sought after because they deliver a hearty portion of meat, offering a more satisfying texture and bite. Their unique shape locks in natural juices, preserving their fresh, rich flavor - something diners truly appreciate. These attributes make them a standout choice for elevating restaurant menus with high-quality seafood dishes.